Lockout/Tagout (LOTO), also called Control of Hazardous Energy, is used in many industries. LOTO is a process that ensures energy-powered machinery and equipment are shut-down properly so they can undergo regular maintenance with no possibility of suddenly starting up and injuring employees.

Want to download this article and read it later? Get the PDF straight to your device.

About Lockout/Tagout

LOTO procedures isolate the hazardous energy sources in machines, which are locked or tagged by a specially trained worker who is the only person who can remove the lock and/or tag. This assures the machine or equipment cannot accidentally start up while undergoing maintenance or service or be mistakenly turned on by other workers.

A Lockout/Tagout program is required whenever machinery or equipment has the potential to harm workers with its hazardous energy. It’s not enough to just turn off the machine; all energy sources must be identified, controlled, isolated and locked.

The Dangers of Hazardous Energy

When it’s not respected and properly controlled, hazardous energy can seriously injure or kill workers and other bystanders. According to OSHA, using lockout/tagout procedures prevents 120 deaths and nearly 50,000 injuries each year.

Injuries resulting from not properly following lockout/tagout procedures can range from electrocution to amputation, and also include burns, crushing injuries, lacerations and fractures. Industrial workers such as electricians, machine operators and installation, service and repair technicians have the highest risk of injuries from uncontrolled hazardous energy.

Hazardous energy sources include:

- Electrical

- Mechanical

- Hydraulic

- Pneumatic

- Chemical

- Thermal

- Potential (Gravity, Springs)

LOTO OSHA Standards

Sometimes LOTO is called “Lock Out, Tag Out, Try Out”, and you may also hear it referred to simply as lock and tag. The Occupational Health and Safety Administration calls the procedures Control of Hazardous Energy (Lockout-Tagout) and lays out the standards for LOTO safety in 29 CFR 1910.147.

These standards require employers and workers to take the proper steps to shut-down and disable equipment to prevent accidental hazardous energy release.

OSHA standards apply to any machine that could unexpectedly start up, energize or release stored up energy, causing harm to anyone around.

OSHA 29 CFR 1910.147 is the gold standard for lockout/tagout policies and procedures, but the organization also references LOTO in other standards including:

- 1910.119 – Process safety management: LOTO

- 1910.261 – Pulp, paper, and paperboard mills

- 1910.269 – Electric power generation, transmission, and distribution

- 1910.306 – Specific purpose equipment and installations

- 1910.333 – Selection and use of work practices

- 1915.89 – LOTO for maritime

- 1917.48 – Conveyors

- 1918.64 – Powered conveyors

- 1926.417 – Circuits

- 1926.702 – Requirements for circuits

Categories of OSHA Standards

The OSHA standards for the control of hazardous energy fall into three main categories: general industry, maritime and construction. Within those categories, the standards are broken down further into subparts.

General Industry

The bulk of the information on LOTO safety is found in 29 CFR 1910.147 in OSHA Rules & Regulations. This section includes information on general environmental controls for the control of hazardous energy.

Within this category, subcategories of standards include Special Industries (Subpart R), which includes policies over pulp, paper and paperboard mills, and electric power generation, transmission and distribution. The second subcategory is Electrical (Subpart S) including specific purpose equipment and installations, and selection and use of work practices.

Maritime

LOTO safety standards from OSHA also cover parts of the maritime industry, explained in 29 CFR 1915, 1917 and 1918. Subparts under the maritime standards are Cargo Handling Gear and Equipment (conveyors); and Cargo Handling Gear and Equipment Other Than Ship’s Gear (powered conveyors).

Construction

The third category of LOTO standards falls under Construction, which has three subparts. Occupational Health and Environmental Controls (Subpart D), outlining process safety management of highly hazardous chemicals. Electrical (Subpart K) provides rules regarding lockout and tagging of circuits and Concrete and Masonry Construction (Subpart Q) covers requirements for equipment and tools.

When OSHA Standards Do Not Apply

The OSHA LOTO Standards do not cover every situation involving hazardous energy. Exceptions to the standards policies include:

- Electrical hazards when working on, near or with conductors or equipment in premise wiring.

- When exposure to hazardous energy is controlled by unplugging the equipment and the employee has exclusive control of the plug.

- When an employee performs hot-tap operations on pressurized pipelines distributing gas, steam, water or petroleum products and continuity is necessary and shutdown is impractical.

- When an employee performs minor service activities (such as tool changes) as part of the normal routine of production during normal operations.

State Plans

Several states enforce their own safety programs independent from the federal OSHA programs. State plans receive funds for 50 percent of the operating costs from OSHA. As of 2019, 28 states had their own safety plans, 6 of which only cover state and local government workers.

Employers in these 28 states must follow the state standards. You can find information on each of these state’s standards via the OSHA State Standard website.

Standards Assistance for Companies

OSHA offers letters of interpretation to companies wanting an additional explanation of the standards and how they apply.

Companies with fewer than 250 employees at a fixed site and no more than 500 employees corporate-wide can also take advantage of OSHA’s consultation services. These services are free and provide onsite assistance in creating workplace safety and health management programs. In return for the help, companies must agree to correct all serious hazards within a certain timeframe.

Companies can have OSHA perform hazard surveys to help them identify problems. The consultation assistance also includes training and education services.

Lockout/Tagout Procedures

The exact lockout/tagout procedures will look different from company to company, but include many of the same steps.

Employees must follow each of the steps exactly and in order to assure that they stay safe. These steps must occur before beginning service or maintenance on machinery or equipment covered by LOTO standards.

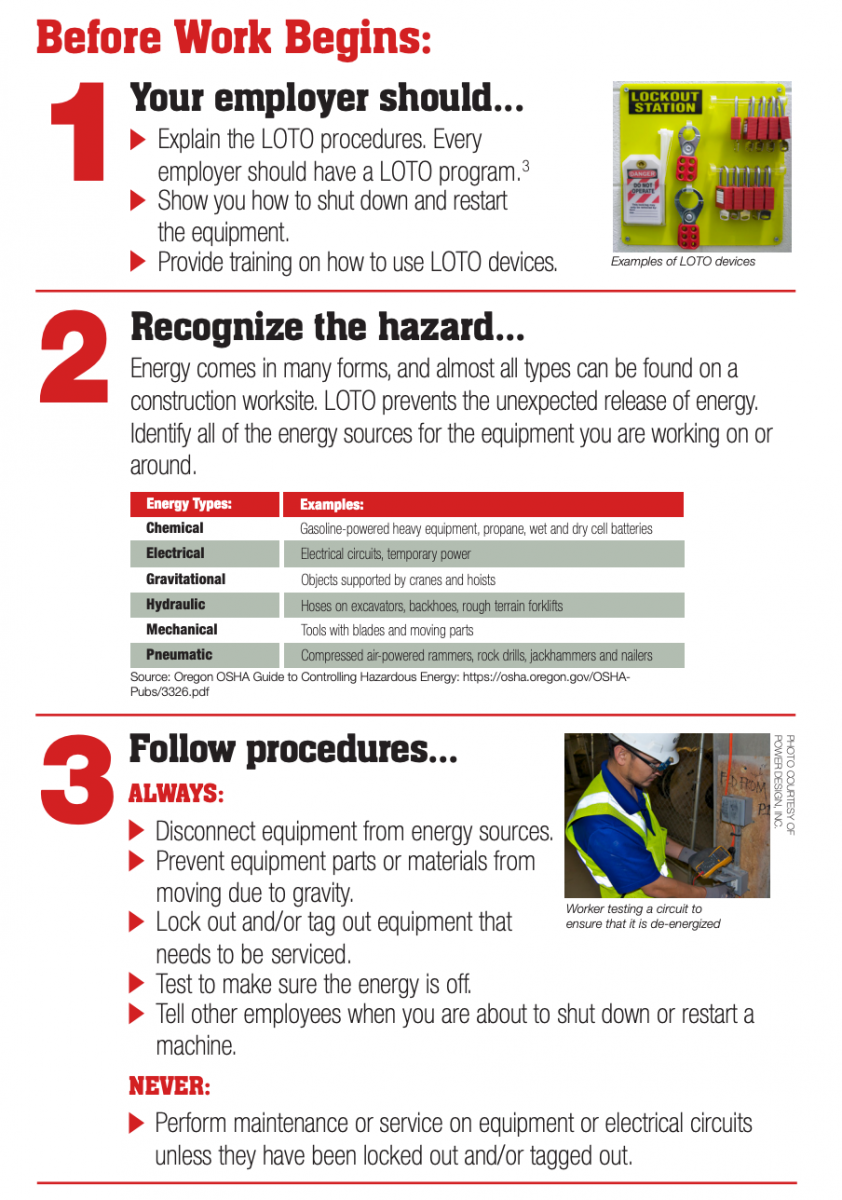

- Prepare for shutdown. This includes making sure the correct equipment has been identified for LOTO.

- Notify employees, alerting any workers who use or will be around that machine that will be locked or tagged out. Let workers know how long the work is expected to take and when the machine will be available for use.

- Shut down the machine, following the specific and detailed instructions provided by the employer.

- Disconnect or isolate the machine from its energy source or sources, including electricity, steam, water, gas, compressed air and others.

- Release or restrain any stored or residual hazardous energy. This can include trapped heat in a thermal system, excess fumes or tension in a spring assembly.

- Apply the lockout and/or tagout devices.

- Verify that all the steps were completed and the machine is safe. Try starting the equipment to be sure the lockout is working.

Once the machine has been serviced or is ready to be put back into use, the employee who applied the lockout/tagout devices should follow these steps (only the employee who applied the LOTO devices may remove them):

- Inspect the machinery or equipment to make sure that it is still intact and the area is clear.

- Make sure everyone is away from the machines, and once they remove the device, be sure that any workers that use that machine know that the lockout/tagout devices have been removed.

When it’s not possible to lockout a device, employers can implement tagout procedures instead. OSHA considers tags as less secure than locks, because tags just warn of danger, while locks provide an actual physical restraint. Tagout procedures include:

- Adding at least one other safety measure that prevents re-energization, such as removing an isolating circuit element, blocking a control switch or opening an extra disconnecting device.

- Applying a tagout device.

OSHA only allows employers to use tagout systems instead of lockout systems if the employer can prove the tagout system is just as effective as a lockout system.

Special Circumstances

Lockout/tagout safety procedures also apply to special circumstances. When an employer uses an outside contractor for service or maintenance, the employer and contractor should educate each other on the lockout/tagout procedures each uses. The employer must then pass that information on to the employees.

Sometimes maintenance is done by a group of workers rather than one person. In these instances, each worker takes control of the hazardous energy source when directly involved in service or maintenance. One worker from that group is the authorized worker, with the responsibility for applying and removing the lockout/tagout device.

Most group lockout programs have a lockbox or other central place where each person working on the machine or system can attach his or her lock. Only when there are no locks on the lockbox (I.e. no one is still working) can the Authorized Person get to the keys necessary to remove locks and put the system back into service.

If maintenance takes place during a shift change, the employer should name an authorized worker for the second shift who takes on the responsibility of removing lockout/tagout devices. The authority moves from the first shift authorized worker to the next shift’s authorized worker.

At times a lockout device or tag may be left on inadvertently. When this happens, the other employees should follow these steps:

- Contact the authorized person’s supervisor

- Double-check the person is no longer on site

- Try to contact the person via cell phone or at their home

- When not able to contact that person, management will authorize the removal of the lockout/tagout following the written emergency removal procedures

- Document the removal and let the authorized worker know of the removal

Tools and Supplies

The lockout/tagout procedure requires using physical tools and supplies, some for the lockout portion and others for the tagging portion. Examples of lockout devices include locks and keys and restraints, while tagout devices include warning signs, tags and management software.

Each piece of equipment or machinery can only have one device to control hazardous energy and employer must provide enough lockout/tagout devices for every machine that needs it.

Regardless of what type of device an employer uses, it must be:

- Durable to withstand workplace conditions including exposure to extreme heat or cold, UV rays, moisture, humidity, high winds or industrial chemicals

- Unable to be removed without excessive force

- Different from any other non-LOTO devices in color, shape, and size

- Not used for any other purposes

- Legible and understandable by all employees

- Not able to be removed accidentally or prematurely

Locks should only have one key or one combination, kept in the possession of just one person (the authorized worker). The lock should also include the authorized employee’s contact information such as name, department and phone number.

It’s recommended that lockout locks be a different color (such as red or orange) so that employees can easily tell them apart from standard security locks.

Tags have to be non-reusable, self-locking, non-releasing up to 50 pounds, attachable by hand and attached with one-piece nylon cable tie or a similar piece. The tag should have some type of warning printed on it, such as “Do not use” or “Do not operate”.

Employers should inspect lockout/tagout devices regularly and replace as needed. An employee must be sure they are only using devices approved for each type of machinery or equipment and following the instructions for those devices.

Find helpful minimum safety procedure examples at OSHA Standards 1910.147 Appendix A, the Texas Department of Insurance, and the Maine Department of Labor.

Creating an Energy Control Program

To better implement LOTO procedures, create an energy control program that includes a safety plan, training, and auditing.

The program should set policies for who can and cannot fulfill the lockout/tagout procedures. Only employees with lockout/tagout privileges (known as Authorized Employees) should be able to both lock/tag and unlock/untag machinery.

The plan should also include exact and specific written procedures for hazardous energy safety. A comprehensive energy control program will also provide training and auditing of the safety plan and procedures.

Putting Together a Safety Plan

A comprehensive energy control plan should be carefully documented and easy to implement and understand. If the safety procedures are the same for all the machines or equipment at your workplace, then only one safety plan is needed.

Workplaces that have machinery and equipment with multiple energy sources, different power connections or separate shut-down control sequences should develop a machine-specific written lockout procedure for each piece of equipment.

Each safety plan must be written out and must clearly explain:

- Exact steps to shut down, isolate, block and secure machines

- The type of hazardous energy and location of each lockout point

- Specific information on each machine, including operating controls

- Specific steps for applying, removing and transferring lockout/tagout devices

- Who has responsibility for lockout/tagout devices and how those employees receive notice when lockout/tagout is needed

- Requirements for testing machines to verify that the lockout/tagout devices and measures are effective

A company’s safety plan should determine which pieces of machinery need lockout/tagout devices. OSHA uses several requirements to determine whether equipment qualifies for lockout/tagout status:

- Has a hasp or other part where you can attach a lock when in the off position

- Has a locking mechanism built in

- Has the ability to be locked without dismantling, rebuilding or replacing the energy-isolating device or altering the energy-control capability

Some equipment and machinery cannot be locked out. In these instances, workers must use a tagout device. The tagout device should be as close to the machine as possible, obvious to anyone who might try to operate the machine.

Any tags must clearly state that the machinery cannot be used until the tag is removed by the proper employees.

The Role of Auditing in LOTO Programs

Employers should engage in frequent inspections and reviews of lockout/tagout procedures. OSHA requires reviewing at least once a year, but reviews other times during the year can add an extra layer of safety to the company.

An authorized employee not currently using the energy control procedures can do the inspection. During an inspection, the inspector must observe several of the authorized employees doing the servicing and maintenance activities while lockout/tagout is underway.

The inspector should also do a review with each authorized employee, going over that employee’s responsibilities for hazardous energy safety. This can be done in a group setting or accomplished one-on-one.

Machine-specific lockout/tagout procedures should also be evaluated annually to ensure they are correct and effective in isolating all hazardous energy sources of the machine. Procedures should be updated as necessary.

When inspecting tagout machinery, the inspector must also do reviews with affected employees.

These inspections should give the employer confidence that employees:

- Follow the hazardous energy safety steps

- Understand their roles in the safety plan

- Use procedures that meet OSHA standards and provide sufficient protection against injury

The inspector must provide certification that shows:

- Machine or equipment inspected

- Date of inspection

- Names of employees involved in the inspection

- Name of inspector

Another way to check your worksite for potential safety issues is by using OSHA’s online Machine Guarding eTool. This eTool helps employers identify potential problems with machines that could cause amputation and injury. It specifically covers saws, presses, and plastics machinery.

LOTO Training

The responsibility for educating and training employees on proper LOTO procedures lies with the employer. By following OSHA’s standards, every company can set up their workers for success when dealing with hazardous energy. Any training program must make sure that employees know the procedures, understand why they are important and can physically perform the procedures.

Your program should cover three main areas: specifics of the employer’s energy control program, each employee’s specific duties and assignments in regards to LOTO safety and an overview of OSHA standards related to lockout/tagout procedures.

The employer can also divide training into three types of employees: authorized, affected, and others. The authorized employees are the ones with the authority to put on and remove lockout/tagout devices. These employees need specific training in:

- Recognizing hazardous energy sources

- Types of hazardous sources found in their workplace

- Energy-control procedures

Affected employees are those who operate the machinery or are in the direct area where the machinery is located. Along with training on the lockout/tagout procedures, they should also be trained in:

- Knowing when energy-control procedures are in use

- Understanding why procedures are necessary and the importance of respecting the procedures and devices

The final type of employee is “others,” which covers any employee who work or will be present in an area where energy control procedures are in process. These employees should be trained on:

- Basic energy-control procedures

- Importance of not attempting to restart equipment which has been locked out

Training should also cover safely verifying and removing hazardous energy from machinery and equipment.

LOTO training isn’t a one-time deal; employers must constantly stay on top of changing standards and policies and re-train employees accordingly. Any new employees should be trained before they start working, and current employees re-trained if they change job assignments.

Employers must provide proof that all employees have been trained. In addition, authorized employees should be observed performing a lockout annually by another trained person, and their performance evaluated and documented to ensure their level of knowledge is acceptable.

The OSHA Lockout/Tagout Interactive Training Program is an online tool that employers and employees can use for training purposes. The training program is divided into three sections: tutorials, hot topics, and interactive case studies.

Tutorials present the standards in question and answer format and the hot topics dive deeper into the topics with detailed explanations. The interactive case studies allow the user to apply the standards themselves in seven real-life scenarios.

Another helpful training tool is the Lockout/Tagout Plus Expert Advisor, a diagnostic software for employers.

Employers looking for onsite training can attend classes at the OSHA Training Institute in Des Plaines, IL. These training classes are also open to federal and state compliance officers, state consultants, federal agency personnel and employees.

Students at the institute learn in a variety of ways, from classroom lectures to hands-on laboratories. OSHA also has 73 local offices with training materials, publications, audiovisual aids, and technical advice.

More LOTO Resources

Using proper lockout/tagout safety procedures isn’t just important for employers, it’s a matter of life or death. By following and applying OSHA’s standards, employers can provide an extra layer of protection to workers doing maintenance and service on machines and equipment with hazardous energy sources.

The following resources can help you improve your LOTO program:

- OSHA Fact Sheet

- Machine Guarding eTool

- OSHA Control of Hazardous Energy – Lockout/Tagout Booklet—Offers explanations for OSHA’s hazardous energy standards.

- OSHA Standard 1910.147—Full text of the OSHA hazardous energy safety standards

- CDC: Using Lockout and Tagout Procedures to Prevent Injury and Death during Machine Maintenance—Brief explanation of OSHA standards

- Control of Hazardous Energy Sources Self-Inspection Checklist for Schools

- Preventing Worker Deaths from Uncontrolled Release of Electrical, Mechanical and Other Types of Hazardous Energy—In-depth look at five real-life fatal accidents and how hazardous energy safety programs can prevent these types of accidents

- Guidelines for Controlling Hazardous Energy During Maintenance and Servicing—Outlines safety methods for protecting workers from hazardous energy

- Lockout/Tagout National Ag Safety Database—lockout/tagout safety information from NASD

- Preventing Cuts and Amputations from Food Slicers and Meat Grinders—OSHA Fact Sheet

- Lockout/Tagout Interactive Training Program

- OSHA Sample Lockout/Tagout Procedure

- Lockout/Tagout Plus Expert Advisor

- Lockout/Tagout Supplies