Statistics show that 42 percent of construction worker deaths involve falls. While this may not be a fixed statistic across all industries, it does highlight the need for better implementation of fall protection PPE and processes.

Choosing a fall protection method that fits your workplace should be treated as a high priority. There is no one-size-fits-all solution. Mitigation and risk factors associated with each fall protection device should be carefully assessed before deciding what is best for worker safety.

Types of Fall Protection

Below are the several types of fall protection methods, listed in the order of the most effective to the least:

Fall Prevention

In this approach, falls are prevented by creating a barrier between the worker and a fall hazard. The goal of this approach is to eliminate the possibility of ever reaching the hazard. Guardrails around unprotected edges, as well as covers over holes, are some of the physical barriers used in fall prevention (more on this later).

Eliminating hazards is the most effective of all fall protection methods. It is on top of the Hierarchy of Controls. In this method, fall hazards are carefully identified, evaluated, and eliminated whenever possible. Removing these unsafe conditions can greatly reduce the incidence of preventable falls.

OSHA Guidelines

OSHA sets the following minimum fall prevention requirements for employers:

- Every floor hole that an employee can potentially walk into should be guarded. This can be done by using a railing, toe board, or covering the hole altogether.

- All elevated and open-sided platforms must have guardrails and toe boards around them. This includes every floor or runway.

- The same physical barriers are required in areas where workers can potentially fall on dangerous machines and equipment.

Some may ask, “why not just use this method for all instances if it is the most effective?”

The answer is that fall prevention is not viable for all types of work environments. Eliminating fall hazards by placing guard rails and physical barriers are not fully possible for certain types of construction and industrial work.

The best advice is to prioritize the elimination of fall hazards. If risks can’t be completely eliminated given the circumstances, other fall protection methods should be explored or added.

Fall Hazard Identification

Identifying fall hazards is not just a task for employers. Workers should also be trained to spot hazards and report them in real-time. They should be familiarized with OSHA guidelines so they can understand the importance of fall protection in the workplace.

Workers should also have some basic knowledge about submitting written reports of near misses and actual falls when they do happen. The present condition of physical barriers should be examined as well:

- Guardrail systems must be inspected regularly to see if they are still in tip-top shape and can hold sufficient weight or force.

- Faulty barriers must be identified and replaced as soon as possible.

This is an ongoing exercise that requires proactive behavior from employers and employees.

Fall Restraint

While fall prevention seeks to eliminate hazards, fall restraint aims to prevent employees from reaching the fall hazard. This can be done through a tie-off system that involves a fixed length lanyard, body harness, or belt.

Fall restraint systems are used when workers need to operate near the edge of a hazard, but not at the exact point of risk. The length of the tie off mechanism must be reasonably shorter than the worker’s distance from the fall hazard. This makes it physically impossible for a worker to reach the hazard.

Fall Restraint VS. Fall Arrest Systems

Fall restraint shouldn’t be confused with fall arrest. While both involve tie-off mechanisms, the goal of restraint is prevention.

Fall arrest, on the other hand, aims to protect employees from deadly contact with the ground in the event of a fall. It is mainly a mitigation measure when a fall has already happened.

In most cases, fall restraint is preferred because it is safer. Though a fall arrest system prevents deadly contact to the ground, it can still result in shock or injury. This is especially true when the employee falls from great heights. This is the reason why it is much better to restrain a worker from reaching a hazard.

OSHA Guidelines

The OSHA does not have any standard specifications for fall restraint systems. However, it is mentioned in Section V, Chapter of the OSHA Technical Manual that it is advisable for fall restraint systems to be able to withstand at least 3,000 pounds of force.

It is also recommended for a restraint system to be able to handle twice the maximum expected force required to restrain the worker.

Disadvantages of Fall Restraint

The number one drawback of this method is that it restricts freedom of movement. This makes it difficult for a worker to reach certain areas of the work zone. In some cases, workers continually adjust their lanyards to move more freely. When done repeatedly and carelessly, this could cause the restraint system to be loose and could lead to danger.

The important thing to keep in mind when using the fall restraint method is to define the scope of the worker’s task. If the task involves closer proximity to a fall hazard, then a fall arrest system can be considered instead. This should only be done whenever necessary.

Choosing Fall Prevention Equipment

The successful elimination of fall hazards requires the use of the right devices. Here are the primary devices used for fall prevention measures:

Guardrails

Earlier, we mentioned the importance of guardrail systems and the vital role they play in fall prevention. With guardrails in place, the need to wear harnesses or lanyards is eliminated. However, in construction sites where workers need to access multiple floors vertically, harnesses and lanyards may still be used despite guardrails being present.

Here are areas where guardrails can and should be installed:

- Rooftops

- Platforms

- Scaffolds

- Balconies

- Mobile work surfaces

- Decked floors

- And many others!

Guardrail Systems similar to MSA’s Versarail system create a physical barrier, preventing employees from working near the fall hazard. The presence of guardrails alone can significantly reduce or even eliminate the incidence of falls.

Toe Boards

Toeboards, meanwhile, are like tiny walls built around the edges of elevated platforms. It’s typically a 2 X 4 inch sized wood that’s nailed horizontally along a roof in various places.

The purpose of the toe board is to prevent tools, objects, and little pieces from falling over an elevation. For example, in the construction industry, some objects like nails, screws, and bolts can fall over the ground. In the absence of toe boards, objects may drop on the floor and cause the workers to go nearer to fall hazards in an effort to prevent objects from falling over.

Toeboards ensure that small objects don’t fall over an elevation so that humans are safe from sudden knee-jerk reactions to “rescue” a bolt or nail.

Hole Covers

The OSHA requires that platform holes in the workplace be covered to prevent people and objects from falling through. The hole cover must be properly installed so it serves as a strong physical barrier with no openings for debris to pass through. Covers can be made out of plywood or steel plates.

Labeling the covers is also important. Without proper labeling, people might just step over the covered hole carelessly. While covering a hole prevents falling, it doesn’t remove the risk of doing so. A cover can be dislodged or removed from its place if stepped on repeatedly. This is why labeling the covers are also important. It reminds workers that danger is still present.

Types of Fall Restraint Equipment

The right equipment must be used to implement an effective fall restraint method. Below are the devices used for fall restraint:

Positioning Lanyards

A positioning lanyard is used exclusively for keeping workers at a safe distance from a fall hazard. It allows employees to safely work within an area while preventing them from venturing too close to the edge.

The lanyard is just one element of a positioning system that supports an employee while working on an elevated surface. The entire system consists of the lanyard itself, a belt or harness, and an anchor point.

This device should never be used for other fall protection initiatives other than restraint. It can be dangerous to use for fall arrest because it cannot withstand the force or impact of an actual fall. Employers should provide their employees with proper orientation on what the lanyard is for, as well as its limitations.

The main advantage of using a positioning lanyard is that it allows the employee to work with both hands. This gives better flexibility and productivity. The downside is that it is not suitable to use when the work area to be accessed is too close to a fall hazard. Also, it cannot be used if the potential free fall is more than 2 feet.

Ladder Climbing Safety Cable Systems

Ladder climbing safety systems such as Miller’s Vi-Go allow employees to safely climb fixed ladders while being safely restrained from falls in the event of a slip. While this may look like a fall arrest system at first, it isn’t. An employee’s belt or harness is fastened to a cable that goes through the full vertical length of the ladder. The worker will be safe from falling if any accidental slips happen.

Fall Arrest Systems

Fall arrest is done to prevent injury, death, or further physical damage when a fall happens. This should only be selected when elimination and substitution are not effective.

Fall arrest should be used as a last line of defense against falls. The reason for this is that fall arrest can still cause body injury, shock, and can even be fatal.

Devices used for fall arrest must be able to absorb strong impact and force while minimizing the risk of a shock for the employee:

Self-Retracting Lifelines (Yo-Yos)

Self-retracting lifelines safely belay an employee to the ground in the event of a fall. It helps limit the distance of the fall by acting like a “seatbelt”.

SRLs have a braking mechanism that immediately stops the harness without pulling its full length during a fall. As a result, there is less force or impact, and a lesser incidence of shock. Fall distances are typically shorter with the use of this device. The braking mechanism locks within inches, not feet, of falling.

Shock Absorbing Lanyards

Shock-absorbing lanyards provide six feet of free fall from the point of anchorage before an additional 3 ½ feet of deceleration is provided to minimize the shock placed on the human body.

This device absorbs the shock and immediate toll of fall arrest on the employee. But while it helps prevent ground impact, there is still a danger from injury.

Here’s why:

There are two factors that directly affect the outcome of fall arrest. First is the weight of the worker, and the second is the fall distance required for deceleration. The lighter the employee, the less impact of the fall arrest. On the other hand, workers with heavier weights have an increased risk of suffering from fall arrest-related injury.

Safety Nets

Safety nets such as DBI Sala’s Sinco Adjust-A-Net are designed to catch personnel in the event of a fall. This is a more straightforward solution, wherein nets are fastened underneath places where workers may fall.

The Bottom Line for Selecting Fall Protection Equipment

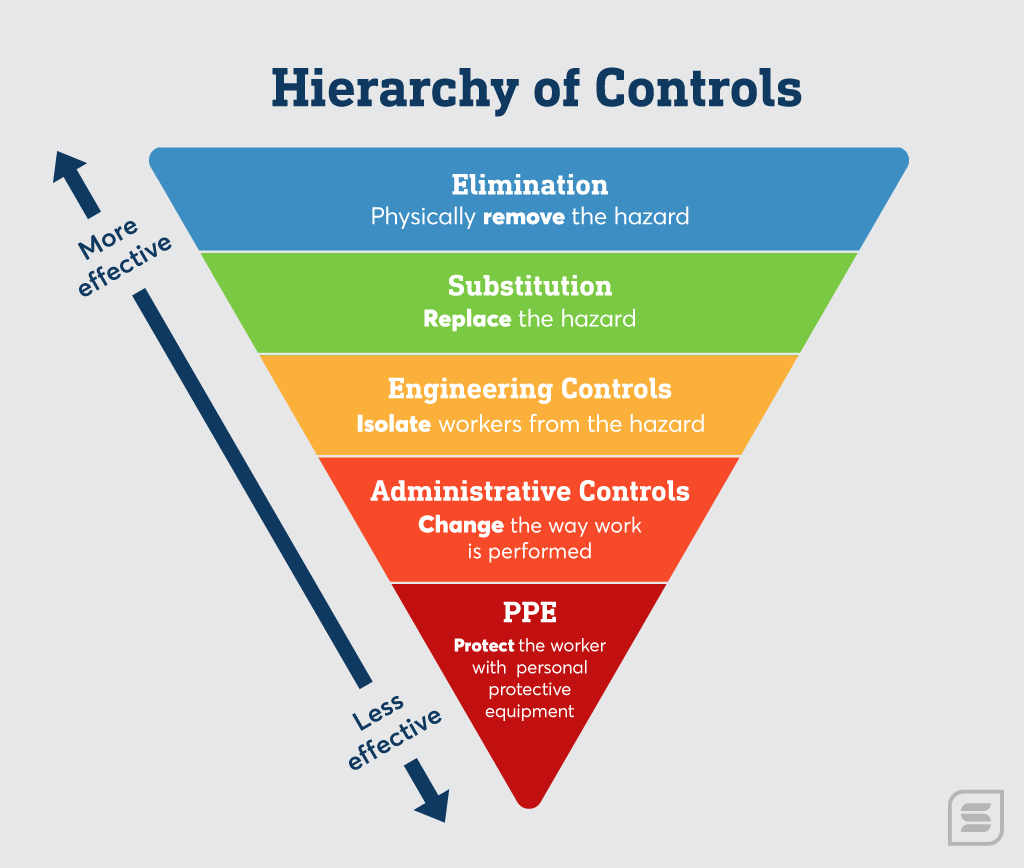

Before you jump into a cost-benefit analysis for selecting your fall protection PPE, remember to apply the hierarchy of controls:

- The first priority is to evaluate ways to eliminate fall hazards (elimination). This is where fall prevention really happens.

- If not all hazards can be eliminated, employers can look for ways to replace those hazards (substitution).

- Engineering controls, meanwhile, aim to isolate people from the hazard. This is where fall restraint comes in.

- Administrative controls aim to change the way people work if they can’t be isolated from a hazard.

- Finally, if all of the above controls fail, the goal must be to protect the worker with the right Personal Protective Equipment. Fall arrest systems fall under this category.

The evaluation and selection of fall protection methods is an ongoing process. As new technology emerges and your organization evolves, so will your decisions regarding work at heights.

To make meaningful improvements faster, track your equipment inspections, fall hazards, and near misses in one place. Safesite is a free app and leading indicators dashboard that gives you a strategic view of your entire safety program. Run a free inspection today >