The first question an OSHA incident investigator will seek to answer is: “Did the employee receive adequate safety training to do the job?”

Throughout its interpretations and citations, OSHA states that an adequate employee training program includes a documented plan, skilled instructors, an effective learning environment, leadership buy-in, and most importantly, results.

In this article, we discuss how OSHA assesses and cites its safety training standards, and how you can go beyond compliance to protect your employees.

What are the OSHA Training Standards?

OSHA believes that training is an essential part of every employer’s safety and health program for protecting workers from injuries and illnesses. Specific training requirements are dispersed throughout the General Industry, Construction, Maritime, and Agriculture regulations.

The standards stipulate which topics/tasks require training, which employees should be trained, how often, the necessary qualifications of the person providing the training, and requirements for training documentation

OSHA’s training standard for all industries can be summed up this way:

- Each employee must be trained in the tasks, situations, and tools they will use on the job.

- This training must be provided by a qualified person in a manner (e.g. language and vocabulary) the employee best understands.

- Training must be performed as often as required for safe operations.

- Training must be documented and stored for a period of time.

Even though all employers are held to this high standard, OSHA lists specifics for training frequency and trainer credentials within various subparts, and the requirements are not always the same.

Jump to:

General Industry Standards

Construction Training Standards

Maritime Training Requirments

Agriculture Training Requirements

Which States Require Additional Training By Law?

While some states have adopted Federal OSHA’s training standards verbatim, other state programs have additional training requirements. Training programs like OSHA 10 and OSHA 30, which are voluntary for companies under federal jurisdiction, are required in some states.

OSHA 10 Training is required by Connecticut, Missouri, Massachusetts, New Hampshire, New York, and Rhode Island when working publicly funded projects of certain contract values.

Nevada requires OSHA 10 Training for all employees at least once every 5 years and OSHA 30 Training for all managers at least once every five years. This applies to all jobs, not just public projects.

California’s training requirements are expanded to include standards such as IIPP (Injury & Illness Prevention Program) and the Heat Illness Prevention Plan for Agricultural and Construction workers.

Maryland has stricter requirements for heavy equipment training.

If you’re covered by a state OSHA program, be sure to know the training requirements for your state.

What is the Best Safety Training Frequency?

OSHA doesn’t provide an ideal training frequency for all topics. The agency instead chooses to generalize: the best training frequency is as often as needed for employees to consistently demonstrate they are able to conduct a given task safely. This heavily depends on the complexity (and sometimes the perceived inconvenience) of a given safety procedure.

Be open to training more frequently if circumstances or employee behavior indicates a need – particularly where OSHA recommends annual training at least every 365 days.

With that in mind, should your philosophy be “the more training the better?”

Not necessarily. If your employees are demonstrating safe practices, “over-training” may frustrate your employees or cause them to disengage.

Additional training should be implemented when your employees demonstrate inadequate safety knowledge or when there is a notable workplace change in job site, hazards, personnel, etc.

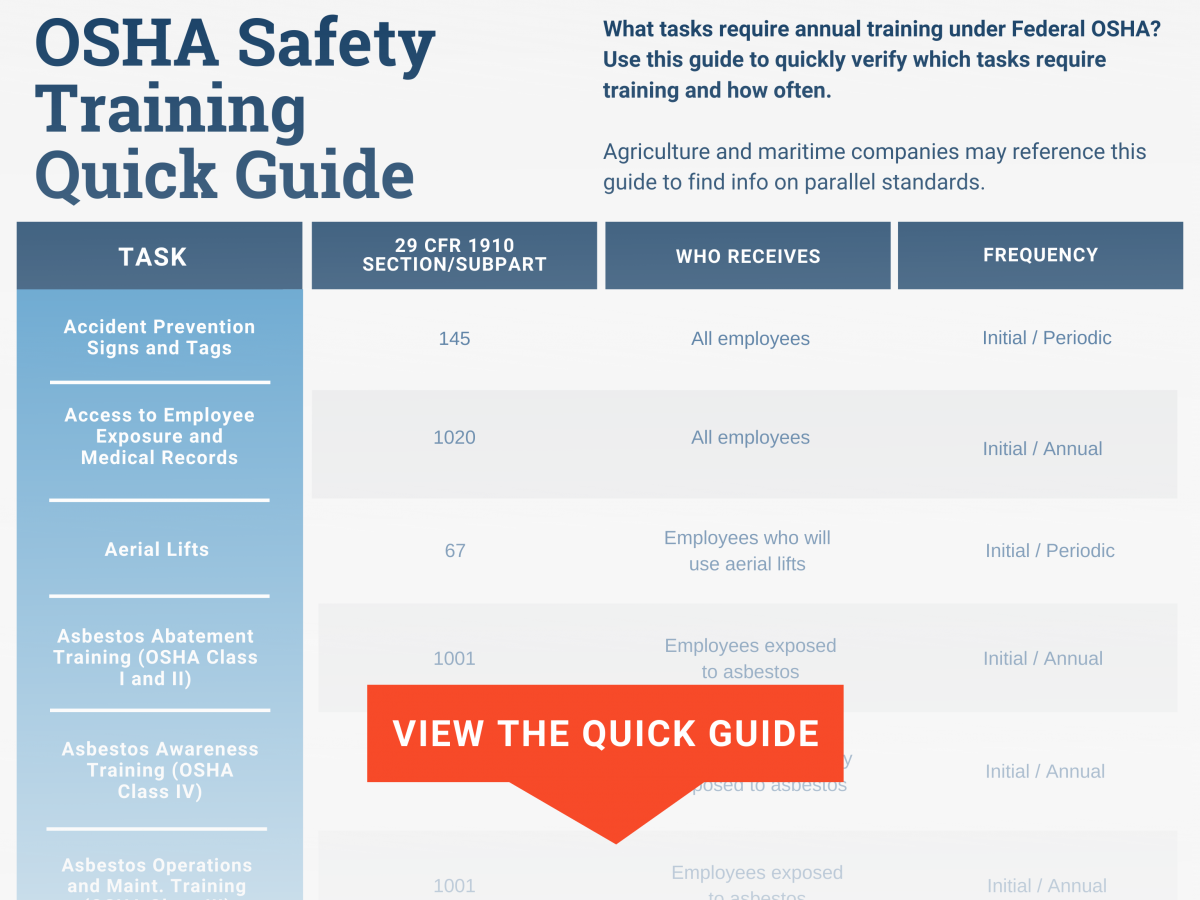

General Industry Training Standards

General Industry Standards for training cover safety essentials for workers. From walking-working surfaces to procedural training for advanced tools and chemicals, it’s vital to know which standards apply to your situation.

The following general industry tasks require initial training (new employee orientation) and annual re-training (at least once every 365 days):

- Access to Employee Exposure and Medical Records and Employee Rights – 1910.1020

- Asbestos Abatement Training (OSHA Class I and II) – 1910.1001

- Asbestos Awareness Training (OSHA Class IV) – 1910.1001

- Asbestos Operations and Maintenance Training (OSHA Class III) – 1910.1001

- Bloodborne Pathogens – 1910.1030

- Ethylene Oxide (ETO) – 1910.1047

- Formaldehyde – 1910.1048(n)

- Hazardous Waste Operations and Emergency Response – 1910.120

- Hearing Protection – 1910.95

- Lead – 1910.1025

- Methylene Chloride – 1910.1052

- Permit-Required Confined Spaces, Rescue Personnel – 1910.146

- Portable Fire Extinguishers – 1910.157

- Respiratory Protection – 1910.134

Some tasks don’t require annual training, but they do require periodic training.

Periodic training is a general term that relates to when additional training is required:

- when workplace changes (new tasks, equipment, procedures,etc.) expose the employee to new hazards

- when employee performance suggests that the prior training was incomplete or not fully understood

The following general industry tasks require initial training (new employee orientation) and periodic/new hazard training:

- Accident Prevention Signs and Tags – 1910.145

- Aerial Lifts – 1910.67(c)

- Arc Welding & Cutting – 1915.252

- Chainsaw Safety – 1910.266

- Compressed Gas Safety – 1910.101

- Confined Space, Authorized Entrants/Attendants – 1910.146

- Control of Hazardous Energy (Lockout / Tagout) – 1910.147

- Crane, Derrick and Hoist Safety – 1910.179

- Diving Safety – 1910.410

- Electrical Safety-Related Work – 1910.332

- Emergency Action Plan – 1910.38

- Hazard Communication – 1910.1200

- Hazardous Waste Management – 1910.120

- Job Hazard Analysis – 1910 Subpart I

- Laboratory Safety – 1910.1450

- Ladder Safety – 1910.25, 26, 27

- Laser Safety – 1910 Subpart I

- Mechanical Power Presses – 1910.217

- Medical Services and First Aid (recommended for general employees) – 1910.151

- New Employee Orientation – Throughout 1910

- Ergonomics, Office, and Labs (recommended) – 1910/General Duty Clause

- Operation of Powered Platforms – 1910.66

- Personal Protective Equipment – 1910.132

- Powered Industrial Trucks – 1910.178

- Process Safety Management of Highly Hazardous Chemicals – 1910.119

- Servicing of Multi-Piece and Single-Piece Rim Wheels – 1910.177

- Storage and Handling of LP Gases – 1910.110

- Storage of Flammable and Combustible Liquids – 1910.106

- Toxic and Hazardous Substances – 1910.1000

- Welding – 1910.253

General industry Training Documentation Requirements

While basic documentation of all training activities is a good idea, general industry tasks with specified documentation requirements include:

- Asbestos Awareness, Abatement, Operations, and Maintenance

- Bloodborne pathogens

- Control of Hazardous Energy (LOTO)

- Emergency Action Plans

- Employee medical records

- Forklift operator certification

- Hazard communication and SDS

- Hazardous waste operations (HAZWOPER)

- Hearing protection

- Laser safety

- Medical services and first aid

- Operation of Powered Platforms

- Permit-required confined spaces

- Personal protective equipment (PPE)

- PSM of hazardous chemicals

- Respiratory protection

For further explanation and specifics on General Industry training requirements review the publication Training Requirements in OSHA Standards.

Periodic training refers to training that is needed when employee behavior suggests that the prior training was incomplete or forgotten, or when workplace changes (new tasks, equipment, procedures, etc.) expose the employee to new hazards.

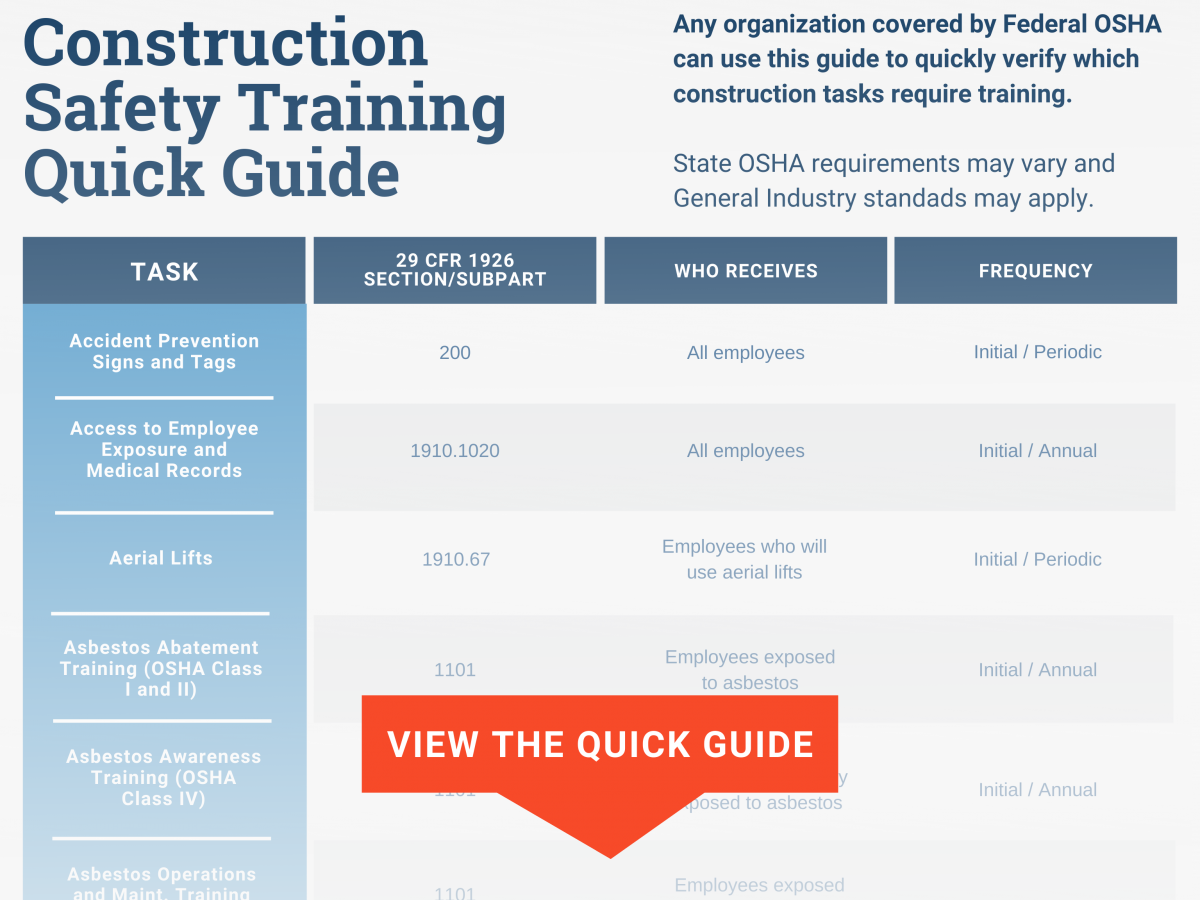

Construction Training Requirements

OSHA’s regulations for construction safety training are dispersed throughout 29 CFR 1926. Review OSHA’s training standards for various tasks and skills, and continue reading for training delivery tips.

Note that training is not required if your employees are not exposed to a particular hazard. For example, if your workers have no risk of exposure to asbestos-containing materials, then you are not required to provide Asbestos Awareness or other asbestos-related training.

The following construction tasks require initial training (new employee orientation) and annual refresher training:

- Access to Employee Exposure and Medical Records – 1910.1020

- Asbestos Abatement Training (OSHA Class I and II) – 1926.1101

- Asbestos Awareness Training (OSHA Class IV) – 1926.1101

- Asbestos Operations and Maintenance Training (OSHA Class III) – 1926.1101

- Bloodborne Pathogens – 1926.1030

- Cadmium – 1926.1127

- Chromium – 1926.1126

- Crane, Derrick, and Hoist Signaling and Working – 1926 Subpart CC

- Ethylene Oxide – 1926.1147

- Gases, Mists, Vapors, Dust, and Fumes – 1926.55

- Hazardous Waste Operations and Emergency Response – 1926.65

- Hearing Protection – 1926.52

- Lead – 1926 Subpart M

- Methylenedianiline – 1926.60

- Operation of Powered Platforms (Bi-Annually) – 1926.66

- Permit-Required Confined Space, Rescue Personnel – 1926.26(6)

- Portable Fire Extinguishers – 1910.57

- Respiratory Protection – 1926.134

- Medical Services and First Aid (recommended for general employees) – 1926 Subpart D

These construction activities require initial training (new employee orientation) and periodic or as-needed training:

- Accident Prevention Signs and Tags – 1926.200

- Aerial Lifts – 1910.67

- Crane, Derrick and Hoist Safety – 1926.550

- Electrical Safety-Related Work – 1926 Subpart K

- Emergency Action Plan – 1926.35

- Hazardous Waste Management – 1926.59

- Job Hazard Analysis – 1926 App B

- Ladder Safety – 1926.1053

- Laser Safety – 1926.1053

- Lead – 1926 Subpart M

- Lockout / Tagout (Control of Hazardous Energy) – 1926.407, 432

- Mechanical Power Presses – 1926.217

- New Employee Orientation – Throughout 1926

- Portable Fire Extinguishers – 1910.157

- Personal Protective Equipment (Eye, respiratory, and hearing protection require annual retraining.) – 1926 Subpart E

- Powered Industrial Trucks (Every 3 Years) – 1926.602 D

- Process Safety Management of Highly Hazardous Chemicals – 1926.64

- Scaffold Safety – 1926.451

- Servicing of Multi-Piece and Single-Piece Rim Wheels – 1910.177

- Storage and Handling of LP Gases – 1926.153

- Storage of Flammable and Combustible Liquids – 1926.152

- Toxic and Hazardous Substances – 1910 Subpart Z

- Trenching & Excavation, Competent Persons – 1926.651, 652, Subpart P

- Trenching & Excavation – 1926.651, 652

- Tuberculosis (Draft Standard) – 1926.1997

- Violence in the Workplace (recommended) – General Duty Clause

- Welding 1926 Subpart J – 1926 Subpart J

construction Training Documentation Requirements

While basic documentation of all training activities is a good idea, construction tasks with specified documentation requirements include:

- Employee medical records

- Asbestos Awareness, Abatement, Operations, and Maintenance

- Bloodborne pathogens

- Cadmium

- Control of Hazardous Energy (LOTO)

- Cranes and derricks operator certifications

- Fall protection

- Hazard communication and SDS

- Personal protective equipment (PPE)

- Emergency Action Plans

- Forklift operator certification

- Respiratory protection

- Hearing protection

- Permit-required confined spaces

- Operation of Powered Platforms

- Medical services and first aid provider certifications

- Methylenedianiline

Many of the above tasks require certification. Be sure to document employee certifications and track when they expire so you can renew them without any lag time.

Find more construction training standards in the publication Training Requirements in OSHA Standards.

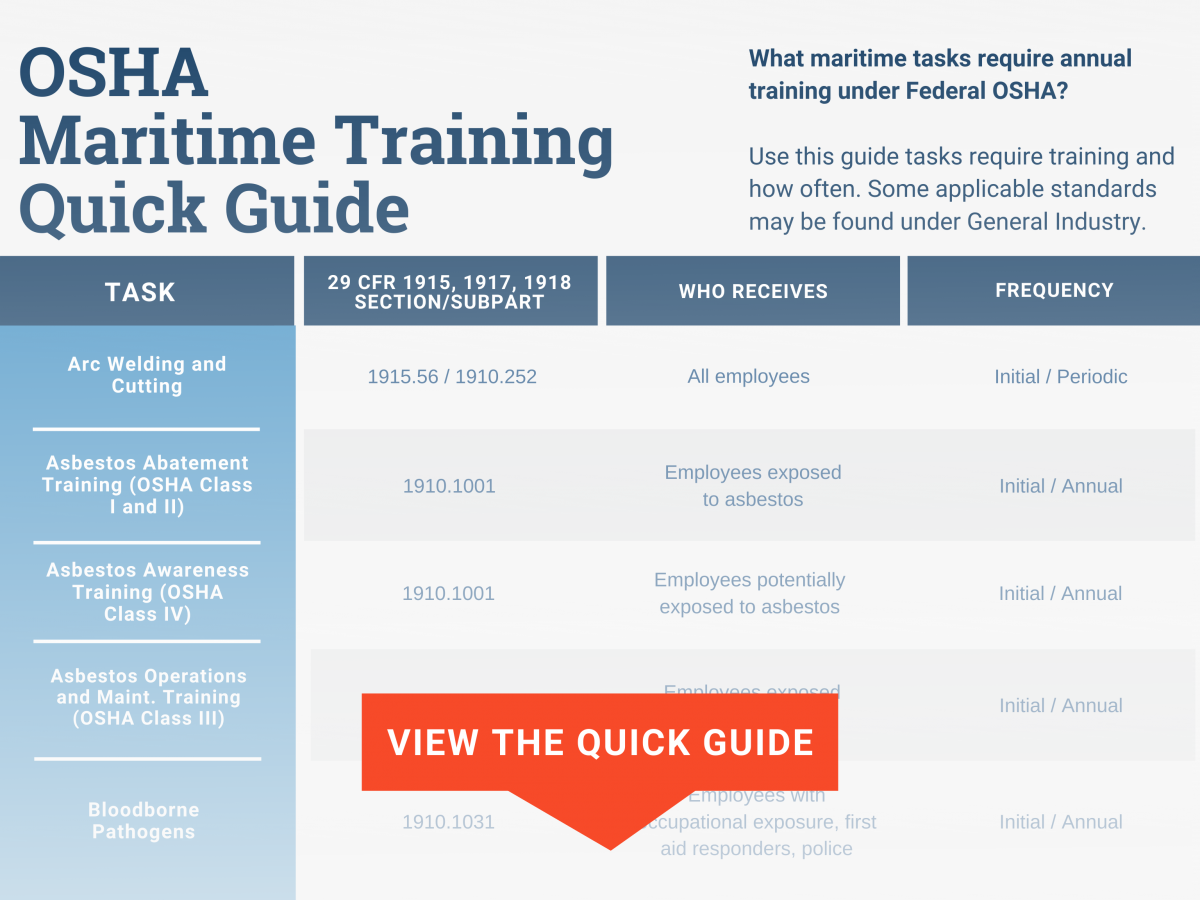

Maritime Training Requirements

The maritime standards have a lot of crossover with general industry standards. Many 1915-1918 standards refer to 1910 for a complete outline of training specifications.

The following maritime tasks require initial training (new employee orientation) and annual re-training (at least once every 365 days):

- Asbestos (OSHA Class I-IV) – 1910.1001

- Bloodborne Pathogens – 1910.103

- Confined Space Rescue – 1915.12

- Crane, Derrick, and Hoist Safety – 1915.117, 118

- Hearing Protection – 1918.1

- Respiratory Protection – 1915.154

The following maritime tasks require initial training (new employee orientation) and the periodic/new hazard training. All tasks require training to perform tasks safely, and some tasks, such as scaffolds and dangerous atmospheres, require the training of competent persons as well.

- Arc Welding & Cutting – 1915.56

- Cargo Handling & Equipment / Vehicle Use – 1917.44

- Confined and Enclosed Spaces and Other Dangerous Atmospheres – 1915.12

- Containerized Cargo: Fall Protection – 1918.85

- Control of Hazardous Energy (lockout/tagout) – 1915.89

- Control of Hazardous Energy (lockout/tagout), Authorized Employees – 1915.89

- Diving Safety – 1915.6

- Electrical Safety – 1918.1

- Emergency Action Plan – 1910.35-38

- Fire Protection – Subpart P

- Fire Watch & Response – 1915.508

- First Aid – 1918.97

- Fissionable Material, Competent Person – 1915.57

- Flammable Liquids – 1915.36

- Gas Welding and Cutting – 1915.55

- Hazard Communication – 1918.1

- Hazardous Atmospheres & Substances – 1917.23,25, 1918.93(d)(3)

- Internal Combustion Engines, other than ships’ equipment – 1915.136

- Ionizing Radiation – 1918.1 / 1910.1096(i)(2)

- Machinery Operations – 1918.98

- Maritime Hazard Testing – 1915.7,9

- Painting Hazards – 1915.35

- Painting Hazards, Competent Person – 1915.35

- Personal Fall Arrest Systems – 1915.159

- Portable, Unfired Pressure Vessels, Drums, and Containers – Subpart K

- Portable, Unfired Pressure Vessels, Drums, and Containers, Competent Person – Subpart K

- Positioning Device Systems – 1915.160

- Powder Actuated Tools – 1915.135

- Rigging: Ropes, Chains, and Slings – 1915.112

- Scaffolds or Staging – 1915.71

- Scaffolds or Staging, Competent Person – 1915.71

- Ship’s Gear – 1915.116,117

- Specialized Terminals: Hydrogen Sulfide and Oxygen Deficiency – 1917.73

- Toxic and Hazardous Substances – Subpart Z

- Vehicles Below Deck – 1915.136

- Ventilation – 1918.94

- Welding, Cutting, and Heating – 1917.152

- Welding, Cutting, and Heating Preservative Coatings – 1917.53

maritime Training Documentation Requirements

While you should document all provided training, maritime tasks with specified documentation requirements include:

- Employee medical records

- Asbestos Awareness, Abatement, Operations, and Maintenance

- Confined space entry

- Confined space rescue

- Control of Hazardous Energy (LOTO)

- Cranes and derricks operator certifications

- Fall protection

- Personal protective equipment (PPE)

- Powder actuated tools

- Emergency Action Plans

- Forklift operator certification

- Respiratory protection

- Hearing protection

- Medical services and first aid provider certifications

Document your employee certifications and track when they expire so you can renew them in advance of the expiration date.

Additional requirements for Marine Terminals and Longshoring operations are contained in 29 CFR Part 1917 and 29 CFR Part 1918 respectively.

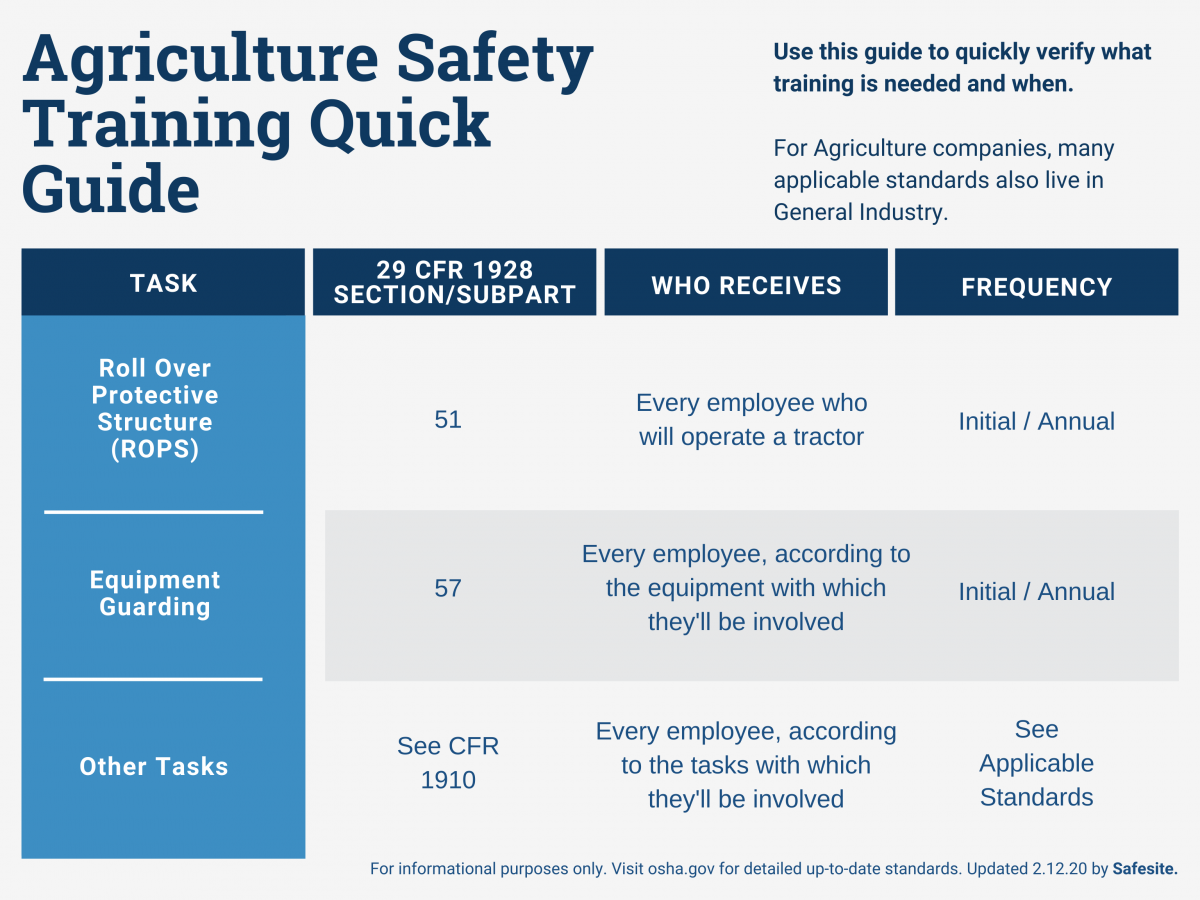

Agriculture Training Standards

The following agriculture tasks require initial training (new employee orientation) and annual re-training (at least once every 365 days):

- 1928.51 – Roll-Over Protective Structures (ROPS) for tractors used in agricultural operations

- 1928.57 – Guarding of farm equipment

- 1928.1027 – Cadmium

Other agriculture-related tasks such as working in Grain Elevators, Food Manufacturing, LOTO, etc. fall under the General Industry Regulations; and many state programs have required training for Heat Illness Prevention for agricultural field workers.

Check your local regulations to establish which training requirements apply to your specific location and type of business.

OSHA Training Documentation and Instruction Requirements

In addition to OSHA’s specific training standards, the agency evaluates companies against overarching standards for training documentation and delivery.

These include storing records of training coursework and attendance for three years, unless otherwise specified, and delivering training by competent instructors in a manner employees understand.

What’s the Best Way to Document Training?

Many OSHA standards stipulate that training must be documented and stored for a period of time. And if you are inspected by OSHA, one of the first things they’ll request is your training records.

Companies may choose to document training in paper files, digital records, or both.

Paper records are inexpensive but must be properly stored and organized so that they are easy to locate when needed.

Digital records allow easy, consistent updates across teams, and, if the software has an export function, can easily be transferred to PDF files for printing.

Whichever format you choose, be sure your employees can understand and use your documentation system with ease.

A good training documentation system includes:

- A process for recording the name of the employee (a signature is not required), the trainer (with signature), training materials or a description of the topics covered, and the date of each training session.

- Proof of competency and an associated date. Proof can be the results of an evaluation or a demonstration of ability. (This only applies to certain tasks under OSHA law, but can be useful to have for every task if you are inspected by OSHA.)

- A way to verify the appropriate records have been created and stored.

- A record storage policy that includes how and when to destroy records when they are no longer needed.

- Record backups.

How Long Should I Store Safety Training and Meeting Minutes?

Where OSHA doesn’t specify a length of storage overall, it does require a certain length for specific tasks. Generally, it’s best practice to hold onto safety training records (curriculum and attendance) for the length of employment.

What is the OSHA Definition of Qualified vs. Competent Person?

Some OSHA standards stipulate that a competent person must manage training, while others reference a qualified person. The definitions of these and other terms related to trainer qualifications can be found within OSHA 29 CFR 1926.32.

A competent person is “capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.”

A qualified person is just a competent person with a specific, verifiable certification or professional standing.

With regard to training, it is important to choose persons that are competent based on capability. This may or may not be dependent upon prior coursework or even certifications. When selecting a competent person, ensure that:

- The trainer is knowledgeable and capable with regard to the topic.

- The trainer is capable of training others.

OSHA 29 CFR 1926.32(m) states that a qualified person is someone “who, by possession of a recognized degree, certificate or professional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated his ability to solve or resolve problems relating to the subject matter, the work, or the project.”

Employers are responsible for ensuring the competent and qualified persons they select for on-the-job training are trained and/or certified (CFR 1926.1430, 1915.7).

What Does OSHA Mean By “In a Manner Employees Understand?”

Many OSHA training standards say that training must be provided “in a manner that employees understand.” OSHA says this statement means, first and foremost, that training must be delivered in the language, vocabulary, and format an employee can best understand.

Simply having a Spanish speaker translate from English during a safety class may not be sufficient for learners to understand. Try to locate a safety professional who is fluent in the language and experienced in providing effective bi-lingual training. (Some training companies specialize in this area.)

Because OSHA stipulates employees must understand training such that they can apply it, OSHA compliance officers will review training documentation and observe employees’ demonstration of safety skills.

Therefore, if training is completed in an employee’s first language but she is still unable to perform her tasks safely, then additional training may be required by law.

Other requirements found within the standards state that understanding must be verified (and documented) before work can begin. Lockout/Tagout (1910.147c) requires employers to verify that the employees have acquired the knowledge and skills which they have been trained through observation.

Spanish Safety Training Resources

In addition to their Spanish language Outreach Program, OSHA lists Spanish safety training resources on their website.

Helpful Spanish training resources include:

- Construction eTool – Spanish

- Sewing ergonomics eTool – Spanish

- Spanish Training Resources – Safety BLR

The free Safesite app is available in Spanish, including features like safety meetings, inspections, and incident reports.

Portuguese Safety Training Resources

OSHA has a number of safety training resources in Portuguese, and the Brazilian Worker Center offers some training in partnership with OSHA.

The Safesite app can be set to Portuguese or French, so that workers can run safety meetings, inspections, and incident reports in their primary language.

Visit OSHA’s website to search for training resources in other languages.

Training Tips and Best Practices

Once it’s clear who requires training and how often, the next step is to determine how best to train. Be sure your program doesn’t involve “going through the motions” of safety training. That will reduce its effectiveness and can negatively affect your safety culture.

Show your employees that you care about their workplace safety knowledge by learning the best methods for training development and delivery or by seeking competent outside trainers when needed.

Read the OSHA publication Resource for Development and Delivery of Training for tips, techniques, and best practices. I’ll discuss a few below.

How to Deliver Safety Training

Your training program should be based on best practices. Put thought into the development and delivery of your training. Even if you start with training courses and templates provided by another company, tailor them to match your workers’ unique needs.

Here are a few practices that every training program should implement:

- Use training materials and syllabi prepared by a qualified individual or institution.

- Training material, teaching, and demonstrations should be accurate and credible.

- Ensure each employee receives training in a language he or she understands.

- Use actionable, practical lessons in your training program. Two-thirds of training hours should include activity-based learning.

- Before training, assess the unique needs of your employees, including language limitations, learning style, test-taking skills, etc.

- Keep classrooms small. There should be a maximum of 25 participants to one instructor.

In addition, your trainers should have the following skills:

- Certification in or a verifiable record of competence in the practices they are teaching

- Training delivery and facilitation skills, including public speaking, practical demonstrations, and the ability to cater a lesson to the audience

- The ability to assess worker competency in the skill they are instructing

- Knowledge of adult learning principles and how to apply them

Online, computer, and video-based training can be used to supplement your training program, but it cannot be the sole form of training workers receive.

Models for Adult Learning

According to OSHA, there are at least three types of adult learning exchanges that you can apply to your training program.

Peer-to-Peer learning happens when your employees learn from each others’ experiences and demonstrations. For example, you provide a role-playing scenario that allows room for each participant to draw on their own experience.

Trainer-to-Participant learning happens when the participants acquire practical skills and adapt sound safety practices through the instruction, discussion, and activities facilitated by the trainer. For example, a trainer runs a demonstration and facilitates the participation of employees in pairs.

Participant-to-Trainer learning includes the lessons a collective group of employees can teach the trainer. For example, as employees take turns sharing their unique experiences, the trainer absorbs various scenarios and cultural perspectives she hadn’t known before.

Use all of the above exchanges for optimum impact on your employees.

How to Develop and Improve Safety Training

You may be able to find existing training curricula and resources to fit your needs. If existing resources don’t fit your company’s situation, you may need to update existing materials or develop your own course.

To develop your own training, familiarize yourself with instructional design best practices. The ANSI/ASSP Z490.1 standard provides guidance on training development and instructional design.

OSHA’s Resource for Development and Delivery of Training encourages the use of the ADDIE model for training development. ADDIE, which stands for Analysis, Design, Development, Implementation, and Evaluation, is a model for all necessary phases of training development.

- Analyze audience needs

- Design training framework

- Develop training materials

- Implement (deliver) training

- Evaluate training efficacy and start the process over

As you develop new training, be sure to keep in mind:

- The most up-to-date safety standards and best practices (not just company rules)

- The needs of your current and future employees

- The settings in which you will deliver training

- The capacity and skills of your instructors

Design for Participation

Two-thirds of your training should include participatory learning. Hands-on activities help you reduce language and literacy gaps, encourage peer-to-peer learning (a highly effective way for adults to learn), and improve learning retention through doing.

To encourage participation, introduce these exercises into your program:

- Demonstrations and practice

- Group discussions

- Ice breakers

- Role-play

- Games

- Risk maps

To avoid putting your learners on the spot, run hands-on activities in small groups.

If your activity involves reading, take measures to reach participants with a limited vocabulary. Keep it simple and use visual aids.

Measure Program Effectiveness

If you have questions about the quality of the training you’re providing, take some time to evaluate your practices. Here are just a few ways to determine the effectiveness of your program:

- Evaluate your processes against OSHA regulations and recommendations. This can be as simple as walking through a checklist and as involved as sitting in on trainings.

- Trend your safety inspections and observations for areas of weakness. Use a safety management dashboard, like Safesite, to show you problem areas revealed by observations, hazards, and incidents.

- Ask your employees where they’d like additional training. Survey your employees to determine areas in which your crews believe they have weaknesses.

- Quiz your employees. Test employee knowledge with anonymous quizzes or with on-the-job interviews.

You can also include questions about safety training in exit interviews, one-on-ones and promotional interviews. This gives your employees a chance to make genuine suggestions for improvement.

OSHA Outreach Training Program

To assist employers in meeting the training requirements, OSHA offers safety training courses via the Outreach Training Program. The courses are voluntary and, according to OSHA are not sufficient for meeting regulatory compliance. They do, however, assist you in educating your workforce and improving your safety program as a whole.

The goal of the outreach training program is to “provide training on the recognition, avoidance, abatement, and prevention of workplace hazards…[and to] provide overview information regarding OSHA, including workers’ rights, employer responsibilities, and how to file a complaint.”

OSHA offers 10- and 30-hour courses to workers in general industry, construction, and maritime. An OSHA-15 course is offered for disaster recovery workers.

OSHA outreach training courses are available in Spanish and English.

About OSHA 10

OSHA 10 is a 10-hour long (total) training course that teaches employees safety fundamentals for their industry.

The course is geared toward entry-level workers in construction, maritime, and general industry.

Typically, six hours of the course is devoted to fundamental hazard recognition and removal. The remaining four houses include elective and optional coursework.

The cost of OSHA 10 will vary depending on the delivery and location of your course. Online OSHA 10 training averages $70 per person, while in-person courses average $300 per person.

Find an online or in-classroom OSHA 10 training provider to see the most up-to-date prices.

About OSHA 30

OSHA 30 is a 30-hour long (total) training course for workers managing the safety of others in any way. There are specific OSHA 30 courses for general industry, construction, and maritime. OSHA-verified trainers must have a trainers’ card for the industry they are

Like OSHA 10, this course covers hazard recognition and response, but the content is more in-depth and covers a wider variety of situations.

Typically, 14 hours are devoted to general safety hazards and best practices. Students can then pick from a menu of elective options (12 hours). Finally, four hours cover optional coursework on additional hazards and policies.

OSHA 30 courses take a minimum of four days (a maximum of 7.5 hours of training is permitted per day).

The OSHA 30 cost depends on the delivery and location of your training. Online OSHA 30 courses average $170 per person, while in-person courses average $600 per person. Find an online or in-classroom OSHA 30 training provider to see the most up-to-date prices.

The OSHA Card

A wallet-sized card is given to employees that complete an OSHA 10-, 15-, or 30- course to verify they successfully completed the course. Only authorized trainers may give out cards.

OSHA 10, 15, and 30 cards do not expire. OSHA says that repeated or continued training is up to you and/or your employers’ discretion. However, some states, like Nevada or New York, do require some form of renewal.

OSHA 10- and 30-hour classes are not provided by the OTI Education Centers themselves. These centers train and verify trainers who can provide OSHA 10- and 30-hour training online or in a classroom near you.

OSHA cards are not a guarantee of employment.

Outreach Program Trainers

OSHA Outreach trainers are not employees of OSHA. Instead, OSHA authorizes qualified trainers through its network of OSHA Training Institute (OTI) Education Centers.

OSHA Training Grants

OSHA provides training grants to nonprofit organizations through the Susan Harwood Training Grant Program. Nonprofit organizations, including qualifying community and faith-based organizations, employer associations, labor unions, and state/local educational institutions are eligible to apply for a grant.

Are You in Compliance?

“Safety starts with training,” according to OSHA. While the agency enforces many standards for safety training topics and frequency, it encourages company leadership to go beyond compliance and seek the best solutions for effective training.

That said, the first question an OSHA incident investigator will seek to answer is: “Did the employee receive adequate training to do the job?” OSHA has demonstrated through documented interpretations and citations that their definition of adequate training includes:

- A Training Plan that outlines the training program’s curriculum development, instructor training, course materials, etc.

- Adequate facilities and resources to conduct effective training

- Students with the basic ability and skills necessary to do the job

- Institutional and administrative support for the training program

Employee training must result in the basic ability and skills necessary to do the job. Regardless of employee attitudes toward training, the responsibility to train lies on your shoulders. Train effectively by incorporating activity-based learning and continually improving your training program.