How many hazardous chemicals do your teams encounter at work every day? The figure is almost certainly higher than you might think. When the chemicals on your premises are deemed Hazardous Chemicals, occupational safety pros have strict obligations via OSHA to protect workers from chemical exposure.

At the same time, the rules around hazardous chemicals are often blurry: exposure limits are very much out of date and the safety data sheets (SDS) provided by chemical manufacturers may not always be the most reliable or easy-to-digest source of information.

To understand chemical hazards in the workplace requires you to grasp the basics surrounding OSHA rules and then dive deeper and go beyond compliance. In this guide, we’ll walk you through an overview of the known information and set you up to take independent steps to manage your chemical safety program.

What Are Hazardous Chemicals?

What is and isn’t a hazardous chemical? Well, the answer isn’t always clear.

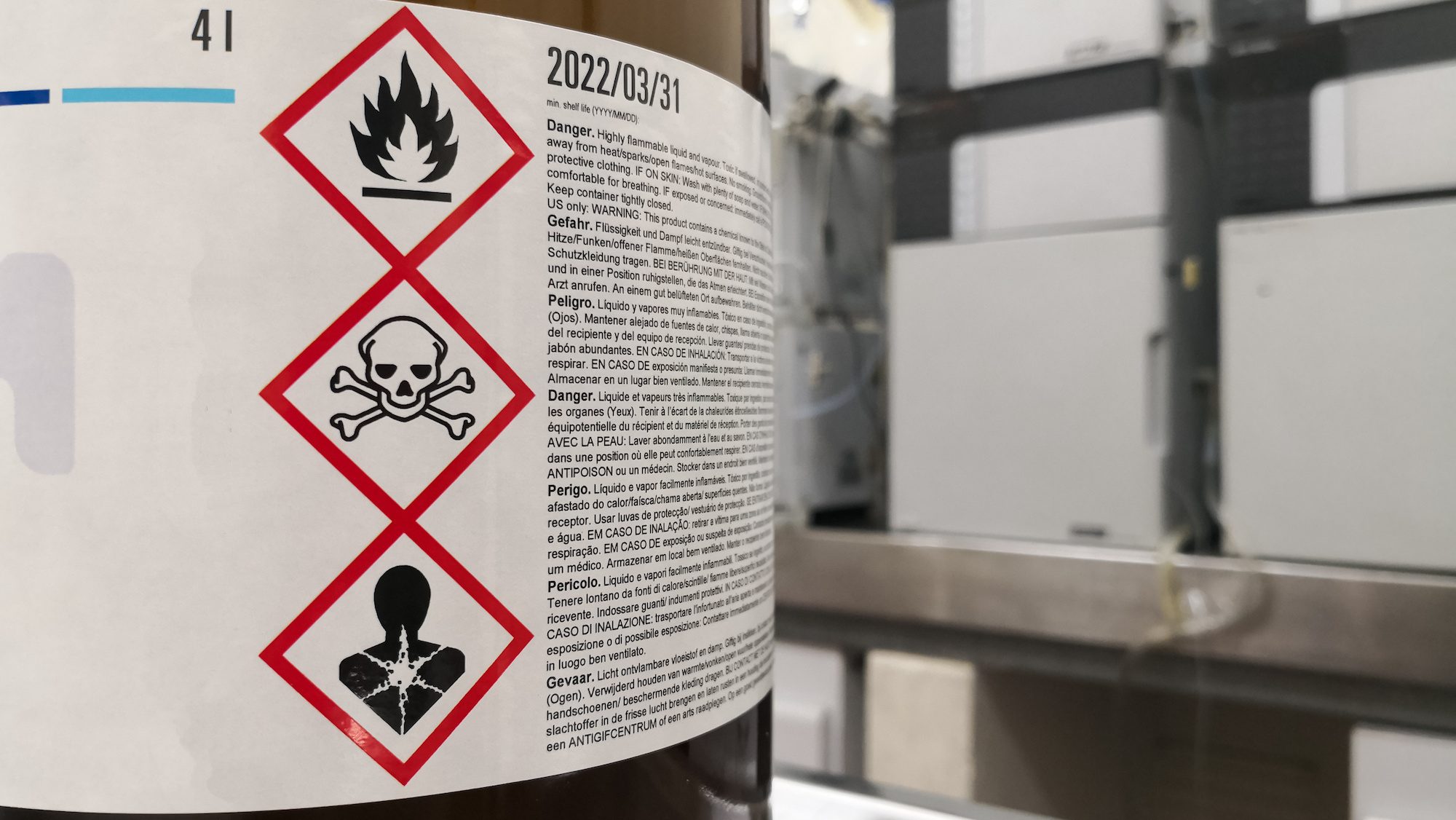

Per OSHA’s general definition, hazardous chemicals are those chemicals that can cause health hazards, like skin irritation or disease, or physical hazards, like fire or corrosion.

What’s unclear about this broad description?

The designation of hazardous chemicals isn’t a centralized process controlled by OSHA or NIOSH. Per CFR 1910.1200(d), the option to label a chemical as ‘hazardous’ or place it under the HCS standard is up to the chemical manufacturer.

The chemical manufacturer has the obligation to not only identify anything deemed hazardous but also to follow Hazard Communication Standard requirements once it lists one of its chemicals as hazardous.

As a result, you’re reliant on your chemical suppliers (or your contractors’ or customers’ chemical suppliers) to let you know when you are working with a hazardous chemical that also comes with OSHA obligations.

What Regulations Apply to Workplace Chemical Hazards?

Several federal OSHA regulations apply to the use of chemical hazards in the workplace. You’ll find most rules in 29 CFR 1910 Subpart H Hazardous Materials (1910.101 to 1910.126).

These are also regulations to define:

- Whether and how to provide worker education and training via the Hazard Communication Standard (HCS), (29 CFR 1910.1200, 1915.1200, 1917.28, 1918.90, and 1926.59)

- What exposure to chemicals is considered to be allowable through OSHA Permissible Exposure Limits (PELs), Occupational Exposure Limits (OELs), and NIOSH Recommended Exposure Limits (RELs) ( 29 CFR 1910.1000; CFR 1926.55; 29 CFR 1910 Subpart Z; CFR 1915.1000)

Hazardous Chemicals vs. Toxic Substances

We tend to throw the terms hazardous chemicals and toxic substances around as though they’re the same thing. You might wonder where the distinction lies given OSHA largely governs both of them using many of the same standards.

However, from a chemical safety and labeling perspective, it’s important to remember that the Environmental Protection Agency considers hazardous chemicals and toxic substances to be distinct.

Hazardous means the substance is one that is corrosive, flammable or ignitable, and reactive.

Toxic substances are those that can be fatal or harmful if you ingest or absorb them.

What’s the difference? A toxic substance may cause injury or illness but only when ingested. It might not necessarily be reactive in any other way. But a hazardous chemical is almost always likely to also be toxic.

In short, a chemical can be toxic or hazardous but it can also be both. The distinctions are important for your Job Hazard Analysis and chemical risk management plans.

How Do Hazardous Chemicals Cause Harm to Workers?

Occupational exposure to hazardous chemicals can have long-lasting human consequences. The damage done usually depends on the specific chemical or substance you’re dealing with.

From an occupational safety point of view, it’s worth noting that very few workers die of a single episode of inhalation of chemicals; in most cases, these fatal work injuries are the product of carbon monoxide poisoning. However, this isn’t a reason to believe that the risk of chemicals is low. Chemicals can contain carcinogens, and both short- and long-term occupational exposure may ultimately result in cancer.

The threat posed by any given chemical changes according to:

- Effects of exposure: Exposure to chlorine might cause eye redness, irritation, and shortness of breath immediately. But another chemical, like asbestos, might lead to long-term effects that aren’t felt for years.

- Chemical potency: There’s a correlation with chemical strength and toxicity. More of a stronger or potent chemical causes more damaging effects. Chemical potency isn’t a fixed number: if ingested, the human body’s metabolism might make a chemical less or even more potent.

- Type of exposure: With occupational chemicals, inhalation and direct contact are the most common forms of exposure. Additionally, the exposure can be mitigated by the length of exposure and the concentration of the chemical.

Additionally, it’s worth noting that not everyone is equally affected by chemical exposures. For people with allergies, the health hazards of certain chemicals may result in far more severe effects. It’s also well known that young children are more sensitive to chemical exposure. Kids can’t metabolize chemicals as well as adults, which leads to absorbing more of the chemical into their bloodstream.

The number of mitigating factors around chemical exposure can make it particularly tricky to work out a chemical risk assessment plan, particularly given the outdated exposure limits and the limitations of the SDSs, which we’ll dive into later.

What are the Allowable Limits for Chemical Hazard Exposure?

Thousands of workers every year experience illness, both short-term and chronic, due to hazardous chemical exposure. One of the most common complaints about occupational chemical exposure is that even though OSHA lists its regulatory Permissible Exposure Limits for “hazardous chemicals,” these limits don’t reflect an accurate or situational risk associated with the chemical.

The issue isn’t new: OSHA began discussing strategies for updating its existing permissible exposure limits in 2014 after the Federal Advisory Council on Occupational Safety and Health urged the president to use an executive order to force OSHA to complete the work.

However, updating chemical exposure limits still isn’t as simple as completing feasibility studies and updating the limits. These studies take years to complete in the first place, and then there are all of the different mitigating factors that impact exposure.

Even still, you need to ensure that chemical exposure remains below OSHA’s pre-determined permissible levels.

The easiest way to find your OSHA Permissible Exposure Limits (PELs) is on the Safety Data Sheet (SDS) provided to you by the chemical manufacturer.

However, if you’d like a more comprehensive look, then most workplaces can find their Permissible Exposure Limits (PELs) under 29 CFR 1910.1000 under Air Contaminants. Construction PELs fall under CFR 1926.55 – Gases, Vapors, Fumes, Dusts, and Mists.

Additionally, you can find Longshoring and Marine Terminals (PELs) under 29 CFR 1910 Subpart Z. The Shipyard Employment PELs fall under CFR 1915.1000 Toxic and Hazardous Substances.

How Are Chemical Hazards Communicated?

Let’s return to the question we asked a few minutes ago: how many chemicals does your team encounter on any given day? There are probably many. These chemicals might include everyday chemicals like bleach, wood dust, paints, solvents, and glue. But you might also work with other specialty chemicals, like mercury or silica, that you encounter less often or that a visiting contractor might bring on to your job site.

How do you share information about all of these chemicals and control the potential exposures?

Hazard communication happens in two ways and is covered by the Hazard Communication Standard (HCS) (29 CFR 1910.1200(g)).

The standard is the rule that requires the chemical manufacturer, distributor, or importer to share the associated Safety Data Sheets (SDSs) (formerly known as MSDS) with customers for each hazardous chemical they purchase. OSHA requires the SDS to contain core information, including:

- Identification

- Hazard identification

- Composition and information about ingredients

- First-aid instructions

- Fire-fighting instructions

- Instructions for an accidental release

- Exposure control and PPE

- Chemical and physical properties

- Reactivity and stability

- Toxicology information

- Ecological description

- What to consider during disposal

- How to transport the substance

- Regulatory statements

- Other information

In addition to meeting OSHA requirements, chemical manufacturers also need to include three sections (Sections 12-15) that match the rules provided by the UN Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

Using the SDS system allows OSHA to better regulate and gain information on the chemicals deemed to be hazardous chemicals. At the same time, you should consider the SDS provided as a starting point for chemical safety at your facility.

Unfortunately, SDSs aren’t incredibly reliable, and you should be particularly careful when relying exclusively on the SDS for a new chemical or an especially hazardous chemical. A study of SDSs for chemicals used in the aerospace industry found that the requirement to provide an SDS doesn’t necessarily translate into a requirement to provide quality information.

Plus, OSHA only requires chemical manufacturers to provide the SDS in English. They have no obligation to provide them in the language of the customers’ workers. The translation of the document is up to each workplace, which means that workers with current or past training in a language other than their native language.

Get Started with Chemical Risk Management

Hazardous chemicals are a part of daily life for many workers, particularly those in construction, manufacturing, agriculture, and longshoring. While there are strict requirements to protect workers from those chemicals, the process is not as straightforward as it could be.

You have OSHA PELs and chemical manufacturer SDSs to help get you started, but these are the foundation of chemical risk management, not the cure. You may find you need to go deeper and act more conservatively than otherwise recommended, particularly if you start seeing the signs of chemical exposure in your workplace.

With the assistance of a safety management solution, you can use existing templates or upload your own to track your chemical inspections, your hazard communication (HAZCOM) inspections, your chemical-safety toolbox talks, and much more.

Learn more about our free app for hazard management and communication as part of a total safety management solution.